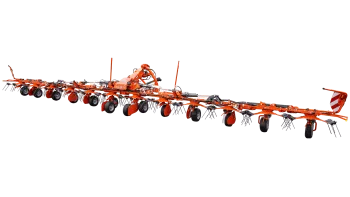

Small rotors speed up drying time by 33%

Our KUHN experts are convinced that small rotors provide many benefits indispensable for producing top quality forage

A large angle greatly reduces drying time.

- Work with a large pitch angle and pick up all the forage.

- Fast and uniform drying.

- Forage turned completely.

- Impressive transversal spread.

- Exceptional ground adaptation.

A large angle greatly reduces drying time.